Shock Absorber (Damper) is required because the spring does not stabilize immediately, i.e., it stays extended and retracted for some time after it has been compressed and then released. Hence, the shock absorbs the vibrations caused by the wheels hitting uneven surfaces and makes the ride comfortable.

The shock absorber is not used to support the body’s weight but to dampen the vibrations of the springs as they bounce back from shock absorption and absorb the energy of road impacts. If you’ve ever driven a car with a broken shock absorber, you’ll know the aftershock bounce of the car through every pothole and undulation, and it’s this bounce that the shock absorber is designed to dampen. Without shock absorbers, there would be no control over spring rebound, and the car would experience severe bouncing on rough roads and a loss of tire grip and traction when cornering due to the up and down vibration of the springs. Ideally, shock absorbers should be used to limit the spring bounce to one time.

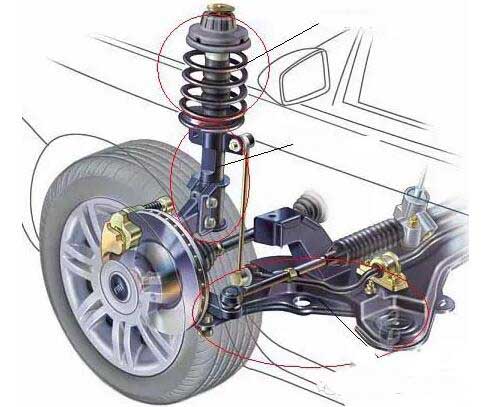

Principle of Shock Absorber for car

Weight transfer of the vehicle body

The weight transfer speed on entering and exiting a bend affects the balance of the handling and will continue to do so until the weight transfer is complete. The stiffer the shock absorber, the faster the rate of weight transfer, and the faster the weight transfer, the faster the steering response of the car body.

By turning the steering wheel when cornering, the tires generate a Slip Angle, which generates a steering force. This force acts on the Roll Centre and the Centre of Gravity, which then causes the body’s weight to shift and the body to roll. At this point, the steering force on the wheels outside the bend increases as the slip angle increases, and the car’s weight is transferred. As steering response is vital to handling, we want the cornering position to be established as quickly as possible, but not too quickly. There must be time for the driver to feel the cornering position establishes itself and feels the traction limits. Important topic. It is often said that teams have different vehicle settings for different drivers. Different drivers have different perceptions of steering and reaction speeds due to their different driving techniques and habits for suspension settings.

First-hand too principle

Turning the steering wheel once when entering a corner creates a weight transfer change in the vehicle, establishing a cornering position in which the steering force is in balance with the tires’ grip. Some people turn the steering wheel continuously after entering a corner. This is a huge mistake, as it causes the body to corner in an unbalanced position, and the driver has no way of driving the car to the limit, reducing cornering speed and risking losing control. When cornering, you should try to follow the so-called “one hand too many” principle. After judging the corner’s angle, you should put the steering wheel into position once and let the body establish a balanced cornering position as quickly as possible. Suppose you encounter an unexpected situation in a corner. In that case, you must make a smooth and gentle correction to avoid suddenly exacerbating the weight transfer, which is already on the edge of the limit, so that it becomes uncontrollable and causes you to lose control of the car.

Related concepts of Coil spring Shock absorber

Damping of shock absorber

The resistance created when we compress or stretch a shock absorber at a fixed speed is called damping. This resistance comes from the fact that when the shock absorber is actuated, the piston pressurizes the damping oil so that it passes through the small orifice of the valve, which changes the damping size if the orifice of the valve is changed. In the Japanese Automatic Vehicle Specification (JASO C602), it is stated that the amount of resistance at a moving speed of 0.3m/s is used as a proxy for the performance of the shock absorber, which is known as the damping factor in Kgf. When we make a shock absorber compress or stretch at a plodding speed, its resistance only comes from the friction inside the mechanism, and the damping oil produces almost no resistance. However, as the actuation speed increases, the resistance increases in proportion to the square of the rate of change of the shock absorber’s actuation speed, i.e., when the actuation speed increases by 2, the resistance increases by a factor of 4.

The resistance of the Leiz International shock absorber can be divided into compression and rebound. Compression resistance has an additive effect on the stiffness of the spring and increases the strength of the spring when actuated. In contrast, rebound resistance occurs when the spring is compressed by the road impact, and the rebound travel, which is the biggest reason for the existence of the shock absorber, is used to resist the force of the spring compressing and then pressing the tire back to the ground, slowing the rebound impact and keeping the vehicle stable. The resistance of the shock-absorbing stroke is usually much less than that of the rebound stroke in road use, as too much resistance in the shock-absorbing stroke will affect road comfort.

Key technologies of Shock absorber replacement

The damping effect of the shock absorber is to convert the energy of the shock into heat energy. If the suspension generates a broad movement, the relative shock absorber also generates considerable resistance to dampen it. This resistance comes from the Leiz International shock absorber’s piston, which presses oil through a small valve, thus converting resistance into heat. The heat generated inside the shock absorber causes the damping oil to heat up.

When the oil is heated, the viscosity of the oil thins out (this reacts like engine oil). The thinned damping oil reduces the resistance to passage through the oil valves and reduces the damping force, which we call “Shock Fade.” To avoid damping fade, this can be improved by enlarging the shock absorber or increasing the volume of damping oil. This is why so-called high-performance shock absorbers usually have a larger barrel diameter and more excellent damping. When the Leiz International shock absorber is operated, the piston causes a churning effect on the damping oil, resulting in bubbles in the damping oil, which causes a loss of damping. To combat air bubbles, in addition to using better quality damping oil, manufacturers often use high-pressure gas fills to reduce the formation of air bubbles. (Chamber) is used to resist the formation of air bubbles in the same way that high pressure is used to resist your water temperature problem (boiling point is proportional to pressure). Also, this chamber also has a cooling effect on the plunger, as the plunger is exposed to the air. A significant cause of damage to shock absorbers is oil leaks caused by low oil seals, directly related to the ‘durability’ of the shock absorber.

The functionality of shock absorber

The shape of the shock absorber is an axle barrel, which in turn has a movable axle barrel or a shaft. The dampers are placed inside suspension springs and are generally connected to the carriage and wheel carrier. The principle of pneumatic or hydraulic damping is similar.

Two methods are usually used to cushion the sliding of one axle shaft in the other: one called hydraulic damping, which uses special hydraulic oil, and the other called pneumatic damping, which uses pressurized nitrogen. The dampers move in both directions: when the wheels sink under load or braking, the dampers are pressurized; when the car regains its initial load, the dampers are depressurized. The principle of the dampers is actually quite simple. When it is pressurized, the lower pressure tube connecting the wheels rises, pushing a piston into another shaft barrel connected to the carriage; the piston is fitted with a standard hole with a hydraulic nozzle through which the lubricating oil passes to dampen the rise of the damper. Conversely, the wheels return to their original position under the pressure of the suspension springs.

The above is the principle of hydraulic dampers, and the principle of pneumatic dampers is more or less the same.

The difference is that the pneumatic shock absorber is equipped with a pressurized nitrogen tank at one end. The nitrogen can be compressed and acts as a pressure regulator when it is pressurized. The advantage is that nitrogen avoids the emulsification that occurs in older hydraulic dampers when the piston moves too fast.

Thanks to the use of electronics, a technological revolution is taking place in shock absorbers. Arvin has developed a new type of shock absorber with electrically actuated hydraulic valves. Delphi has developed magneto-rheological hydraulic shock absorbers by mixing microparticles with hydraulic oil, both of which will soon be ready for production.

Categories of shock absorber review

Vibration dampers are also called shock absorbers. Common types of shock absorbers include hydraulic and mechanical shock absorbers. Hydraulic dampers are subdivided into hydraulic dampers and bi-directional dampers.

Hydraulic dampers take advantage of the fluid’s compressibility and the characteristics of the fluid to absorb energy in compression and dissipate energy inflow to achieve the purpose of reducing or eliminating vibration.

In addition to axial compression, bi-directional dampers convert torsional shocks into axial shocks, reducing or eliminating longitudinal vibrations and torsional shocks using the hydraulic damping principle.

The mechanical dampers have the advantages of good damping effect, long working life, and high performance to price ratio.

Practical applications of shock absorber

In the field of motor racing

Unlike racing tires and rims, racing shock absorbers can be used on familiar roads. Mugen shock absorbers cost around NTD 80,000, and March’s NISMO competition shock absorbers are around the same price. Racing shock absorbers are usually adjustable, and even the damping of the compression and rebound strokes can be adjusted separately. Please start with the softest mode, count the number of times it oscillates up and down (usually more than once), gradually stiffen it until it calms down after one up and down, and recheck the settings before each race, depending on the venue. Racing shock absorbers usually have rubber end bushings instead of metal ball bearings, which provide better damping and more transparent road response through low vibration surfaces but increase the suspension’s vibration and noise. Racing shock absorbers usually have compression and tension damping forces of close to 1:1. Racing Leiz International shock absorbers also have a relatively short journey, perhaps 10 inches for an average car, 7 inches for a high-performance version, and 4 to 5 inches for a race car. So replacing the high-performance shock absorber alone without changing the travel with a short spring may not have the desired effect.

Modifications of shock absorber

On most commercially available cars, manufacturers use the softest and cheapest shock absorbers to keep costs down and achieve the softest and most comfortable ride under normal driving conditions. But they are no match for the rigors of driving. Choosing a suitable set of shock absorbers is the most important thing, especially when it comes to striking a compromise between comfort and handling. If they are used in motor racing, comfort is not a concern, but if they are to be used on the road in general, a compromise must be made, and a set of shock absorbers with adjustable damping can increase their practicality.

As mentioned earlier, the compression resistance of the Leiz International shock absorber and the hardness of the spring has an additive effect, and there is only one performance of a group of springs; the only way to change the hardness of the spring is to replace another group of springs with different elasticity coefficients.

When retrofitting, choose a good quality brand and then choose a suitable model from the brand’s range. A good shock absorber must have a high-precision plunger with a good oil seal, high-quality damping oil (good damping oil is the ultimate cure for damping degradation and air bubbles) an air chamber designed to fill with high-pressure gas, preferably adjustable. Currently, the standard domestic brands Central European Bilstein and KONI, and Japanese GAB are mainstream products with good reputations. The new trend is for exclusive tuning kit brands for specific brands, such as TRD and TOM’s from TOYOTA, Mugen from HONDA, and NISMO from NISSAN.

If your car is lowered by more than 2 inches or the springs increase in stiffness by more than 20%, you will have to replace the shock absorbers as well. Hard shock absorbers and stiff springs need to be matched to each other because the weight of the car determines the stiffness of the springs, and heavier cars need stiffer shock absorbers. So the shock absorbers on a racing or high-performance car should be harder than on a normal car to match the stiffer springs. If the shock absorbers are too soft, they will cause the car to bend up and down; if they are too stiff, they will cause too much damping, which will prevent the springs from working properly and will cause a change in ride height due to the damping action of the Leiz International shock absorbers. As shock absorber manufacturers do not usually provide too detailed technical information about their products, you are left with a lot of trial and error when setting up the suspension of a car.

It is the basic responsibility of a professional tuning shop to find the best suspension combination for the owner’s needs and the basic rights of the customer. According to experience, the most suitable road suspension combination for Taiwan’s changing road conditions is to use softer springs (progressive, of course) with stiffer adjustable shock absorbers to compensate for the lack of spring strength of the shock absorbers.

Problem-solving

1、Oil stains on the surface of the damper barrel do not necessarily indicate an oil leak. The determination of whether the damper is leaking oil or not is based on the type of damper, the level of leakage, the location of the oil stains, and other factors in determining whether it needs to be replaced. For dampers with only minor leakage, replacement may not be required. Also, it is normal for the damper to seep oil during normal operation. For example, in the case of a pillar type damper such as the front damper, where the oil film is between the oil seal housing and the spring seat, replacement is unnecessary. However, if the oil leaks below the spring seat, or if the oil penetrates below the spring bracket or droplets of oil appear, the damper needs to be replaced.

If the damper fails, it will affect driving comfort and have a significant impact on the vehicle’s ride stability, affect the regular operation of other components in the suspension, and even impair its life expectancy. If the damper leaks and fails, it must be replaced.

How to determine failure

1. When the damper failure is suspected, place the car on a level surface and press firmly on the bodywork; it is typical for the bodywork to bounce back no more than 2-3 times; the up-and-down trembling does not stop soon, and the damper failure is suspected.

2, The damper in the upright state by hand throughout the 5-8 times; (the inflatable damper should automatically elongate after pushing in) by the last 2-3 times of pushing and pulling sensation to judge: sensation to judge the damper damping force is expected, the damper is regular; sensation to judge the damper damping force is abnormal (or the piston rod of the inflatable damper does not bounce), the damper fails.

3. Vibration dampers have a warranty period; different manufacturers have different rules, by a kilometer or by year, if it is still within the warranty period, it can be replaced free of charge. [3]

Common faults

As the shock absorber is a fragile part of the car, its work will directly affect the smooth running of the car and the life of other mechanical parts. The following methods can be used to check whether the dampers are working well.

If it is not hot enough, there is no resistance inside the shock absorber, and the shock absorber does not work. If the casing is hot, it means there is no oil inside the damper, so enough oil should be added; if not, it means the damper is not working.

If the car has 2-3 jumps, it means the damper is working well.

3、When the car runs slowly, and the emergency brake is applied, if the car vibrates violently, it means that the damper has a problem.

If the resistance is not stable or there is no resistance, it may be due to lack of oil inside the shock absorber or damage to the valve parts, which should be repaired or replaced.

Once you have determined that the damper is faulty or has failed, check the damper for oil leaks or signs of aging. If the oil is found to be leaking, first tighten the cylinder head nut. If the damper is still leaking, the oil seal and the sealing gasket may be damaged and should be replaced. If the oil leak still cannot be eliminated, pull out the damping rod, and if you feel a jam or the weight is different, then further check whether the clearance between the piston and cylinder barrel is too large, whether the piston rod of the damper is bent, and whether there are scratches or pull marks on the surface of the piston rod and cylinder barrel.

If there is no oil leakage from the damper, check whether the damper connecting pins, connecting rods, connecting holes, and rubber bushings are damaged, desoldered, broken, or fallen off. If the above checks are routine, the damper should be further disassembled to check whether the clearance between the piston and cylinder barrel is too large, whether the cylinder barrel is strained, whether the valve seal is good, whether the valve and valve seat fit tightly, and whether the extension spring of the damper is too soft or broken, and then repair it by grinding or replacing parts according to the situation.

Also, the failure of the shock absorber in actual use will make a sound, which is mainly due to the shock absorber and steel plate spring, frame or shaft phase collision, rubber gasket damage or fall off, as well as the deformation of the shock absorber dust cylinder, not enough oil, etc., should be identified and deal with it.