Once you have learned about espresso, you will be deeply curious and concerned about espresso machines. How exactly do they work to produce a good variety of fancy coffees with espresso and milk?

Most espresso machines do the same thing: they pour hot water into the ground coffee.

In this issue, we explore how espresso machines work by following the water flow from the water source to the coffee grounds.

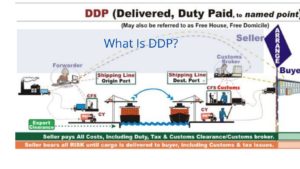

In most machines, the water goes through four different stages before it touches the cup.

☛ water source ☛ mercury ☛ boiler ☛ group leader/steam wand

☛ Water source

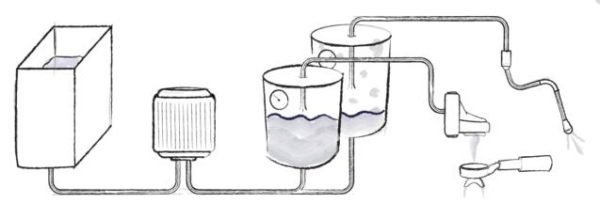

Every espresso machine needs water to function.

For home espresso machines.

Water can come from two separate sources: a water tank located in the machine or a pipe connection between the steady water supply.

Usually, the source of water depends on how the machine is used. For example, coffee machines designed to produce small quantities of high-quality espresso and latte per day are usually equipped with a water reservoir.

Water reservoirs

Advantages: the water quality can be easily adjusted without relying on the water coming out of the tap. Easy to set up, small footprint

Disadvantages: requires occasional cleaning

The high-quality water filter tank allows the water to be conditioned to meet SCAA quality standards.

Large domestic or light commercial espresso machines.

It is essential to maintain a steady supply of water; these machines are usually installed in pipes and rely on built-in or whole house softening and filtration systems.

Pipe insertion

Advantages: no need to fill the water tank before

Disadvantages: some plumbing will be required, and the worktop may need to be modified to accommodate the plumbing

Some hybrid machines can either lead hammer directly or flush with a storage tank; this feature is at the high end of the E61 scale and is ideal for consumers who are not yet sure if the plumbing is feasible.

☛ Mercury

Mercury is known as the heart of the coffee machine.

In-home espresso machines, electric mercury is divided into two categories: vibrating mercury and rotary vein mercury.

Vibrating mercury.

Works through a piston, like a diesel engine connected to a magnet with a metal or copper coil inside. Electric current flows through the metal coil, which causes the interest to move the piston back and forth rapidly, pushing it up to 60 times per second.

Advantages: cheap, easy to replace, small size

Disadvantages: short life span, vibrations make the coffee machine noisy

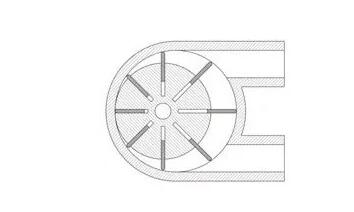

Rotating vein mercury.

Practically mechanical, it consists of a circular chamber with a disc in which the disc will rotate; as it turns, it will increase in force with the movement, water enters the room and then comes out under the influence of the rotating disc.

Advantages: longer life, quiet operation

Disadvantages: more expensive

It is important to note that both pumps produce excellent espresso.

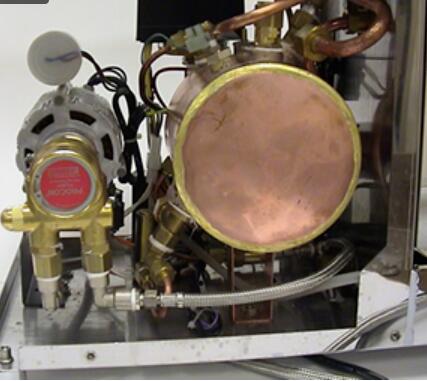

☛ Boiler

The boiler is where the machine is heated, pressurizing, and heating the water to turn the coffee into espresso.

The primary function of the boiler is to heat and control the temperature.

Principle of operation.

Modern espresso machines usually use a heating element to heat the water to a specific temperature. The heating elements are not that intelligent, and most function in an on/off fashion: when they are on, electricity flows through the part, thus producing heat; when they are off, they are out.

Materials: copper and stainless steel

The main characteristics of copper boilers are useful extension and fast heat transfer, which can directly affect heating’s overall uniformity.

On the other hand, Stainless steel boilers have the advantage of being less prone to corrosion, relatively durable, and more affordable.

It is essential to consider the boiler’s size; the larger the boiler, the more coffee the machine will be able to produce, but the more energy and time it will take to heat all the water.

☛ Group head

The group head is one of the last stops in the flow of water through the espresso machine.

All group leaders consist of four essential parts: a filter, a position for locking the filter, a way to activate the mercury, and a path for the water to flow from the boiler to the filter.

There are three main styles of group leader: E61, saturated and semi-saturated

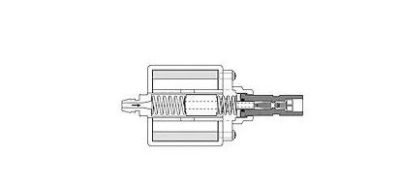

Group Leader – E61.

Patented initially by La Faema in 1961, the E61 group head is a classic component of espresso machine design.

Principle of operation: When making coffee, when the mercury is activated, the Preinfusion valve and the drain valve are closed, while the inlet valve is open (the cam holds the top lever of the inlet valve against it), and of course, hot water enters the various open lines and chambers of the brewing head. When the pressure rises above 1.5 atm, the Preinfusion valve opens, and the hot water enters the Preinfusion chamber. The hot water then moistens the coffee cake, and a cup of espresso is obtained, requiring hot water pressure up to 8-10 atm.

Group leader – saturation.

Principle of operation: Upon start-up, the 3-way valve opens the line to the boiler and the dispersion block while closing the waste line, which allows the ambient pressure of the hot water to pass through the dispersion block to slowly soak the coffee. After the mercury has started, the full pressure is applied to the water, pushed through the open line, and out of the dispersion block. When the spraying is complete, the mercury is deactivated, and the three-way valve closes the line to the boiler while opening the wastewater line.

Group length – semi-saturated.

Principle of operation: The area directly above the dispersion block is separated from the boiler; instead of the entire head being exposed to the boiler, the Gicleur line runs from the extension boiler to the drying zone above the dispersion block, which is connected to a similar three-way valve, which is connected to the dispersion block and a third waste line.

Group leader – Portafilter.

Portafilter stands for portable filter and is a metal filter basket set inside the handle. Ground coffee grounds are placed in the filter basket and then compressed by tamping before being inserted into the Portafilter and locked into the coffee machine.

Related posts